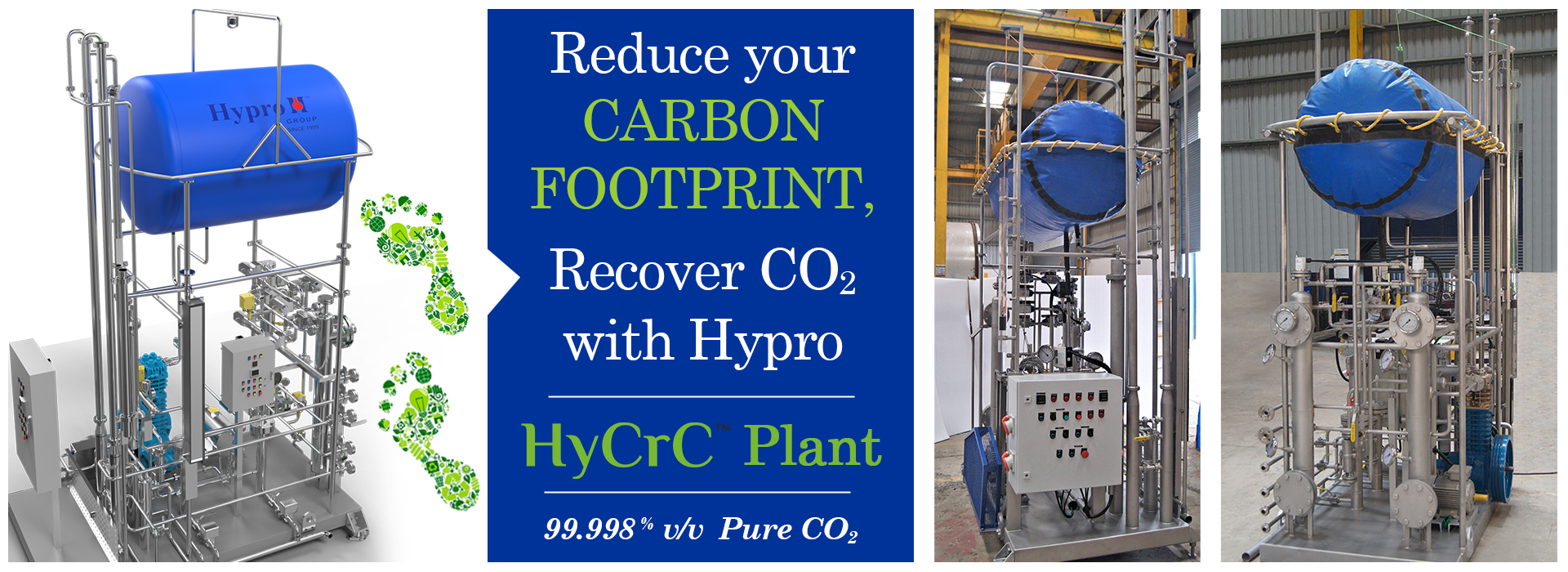

CO2 Recovery Plant

Small efforts have a big impact!

For CO2 demands craft breweries invest in buying it from the market. The carbon dioxide sold by the local sources may come after the recovery of CO2 from flue gas generated during the burning of oil/diesel or it may come from a biogas plant or a distillery or a chemical plant. To use this carbon dioxide, a craft brewery needs a CO2 cylinder station, distribution network, and manpower to handle the gas. To know if the gas is food grade or not complex analytics are needed. Hypro offers to you HyCrCTM Plants which would make your job simpler. With this CO2 Recovery Plant, you are sure you get only pure CO2, the source being the fermentation of your own craft beers.

Empowering the breweries to reduce

Carbon Footprint!

01

Product Description

This CO2 Recovery Plant is well-engineered to collect CO2 in vapor form, convert it into liquid so as to increase the storage capacity in minimum possible floor area, and evaporate the liquid to vapor form to be used back in the brewery and that too by recovering energy. An operator is provided with a panel that serves as an interface between the plant and the human being. The operation panel is simplified for use by the brewer or assistants and eliminates the need for a dedicated operator.

02

Functionality

Breweries need to connect all of the raw CO2 generated, electrical power, water, glycol, compressed air to the inlet of plant and HyCrCTM will deliver pure CO2 > 99.998 % v/v at the outlet of plant and at 7 Bar g Pressure in vapor form.

03

Features

- Produces 15 kg/hr and above Liquid CO2

- Produces CO2 with purity in excess of

99.998% v/v - 100% food-grade CO2 from a known source

- High-grade surface finishes and weld seams

- Complete contact parts built in SS 304

- Optimal Pressure: 16-18 Bar g for efficiency

- CO2 Low-Pressure Purification (Foam washing and removal of water-soluble impurities)

- CO2 High-Pressure Purification for moisture and odor removal

- Glycol-based liquid CO2 Evaporation with energy recovery feature

04

Advantages

- Compact Design

- User-friendly & hassle-free operation

- Minimized Flashing Losses for maximum CO2 recovery

- Design versatility, allowing all the functions to be combined in fewer vessels for the economy, or separated into several vessels for increased capacity

- Eliminates handling of CO2 cylinders

- PLC operated fully automatic with remote access

- Reduced CO2 Consumption: 1.5-2 kg/hl

05

Components

- CO2 Buffer Balloon

- CO2 Compression

- CO2 Condensation using a refrigerant with low GWP

- CO2 Distillation / Rectification

- Liquid CO2 Storage

- Optional add-on HySAAA module for plant and maintenance management with MIS reporting

We would love to see you on social media!

Compare with similar products

Hypro MEE CO2 Recovery System

- 120-1000 kg/hr Liquid CO2 produced

- Recovers CO2 from Breweries, Distilleries, Wineries, Biogas, and Chemical Plants

- Ideal for large scale production

Hypro HyCrCTM Plant

- Up to 120 kg/hr Liquid CO2 produced

- Recovers CO2 from Breweries, Distilleries, Wineries, Biogas, and Chemical Plants

- Ideal for small scale production

Supercritical CO2 Recovery Plant

- Up to 700 kg/hr CO2 produced

- Ideal for Supercritical Hops Extraction

- Ideal for large scale production

Frequently Asked Questions.

CO2 is required for the carbonation of the beer which is an essential step in beer brewing as it forms the beer bubbles.

An ideal way to achieve pure CO2 is to utilize carbon dioxide from your own source. CO2 is produced during fermentation in beer making. Why not recover the CO2 from your own brewery which guarantees perfect quality control – a benefit that no other source can offer.

Continuously changing climate conditions have a potential demand to alter traditional brewing practices that have been passed down to generations. CO2 Recovery is a necessary practice that should be implemented by not only Industrial breweries but also Microbreweries in order to reduce carbon emissions and thereby save mother earth.

The recommended CO2 pressure range is between 7 to 38 PSI depending upon the style of the beer such as Ales, Lagers, Pilsners, and Stouts, etc. An inaccurate pressure may result in under or over carbonation. This may have adverse effects like flat or overly foamy beer.

Often Combined with

If you are planning to set up a Microbrewery/Brewpub or already have one, Hypro offers a complete solution that is totally customized as per your needs. Hypro HyCrCTM is the small scale CO2 Recovery Plant specifically designed for craft breweries. We have successfully commissioned Microbrewery Plants along with Hypro HyCrCTM Plant in order to make the breweries self-reliant on CO2 supply, all the while contributing to the greener earth.